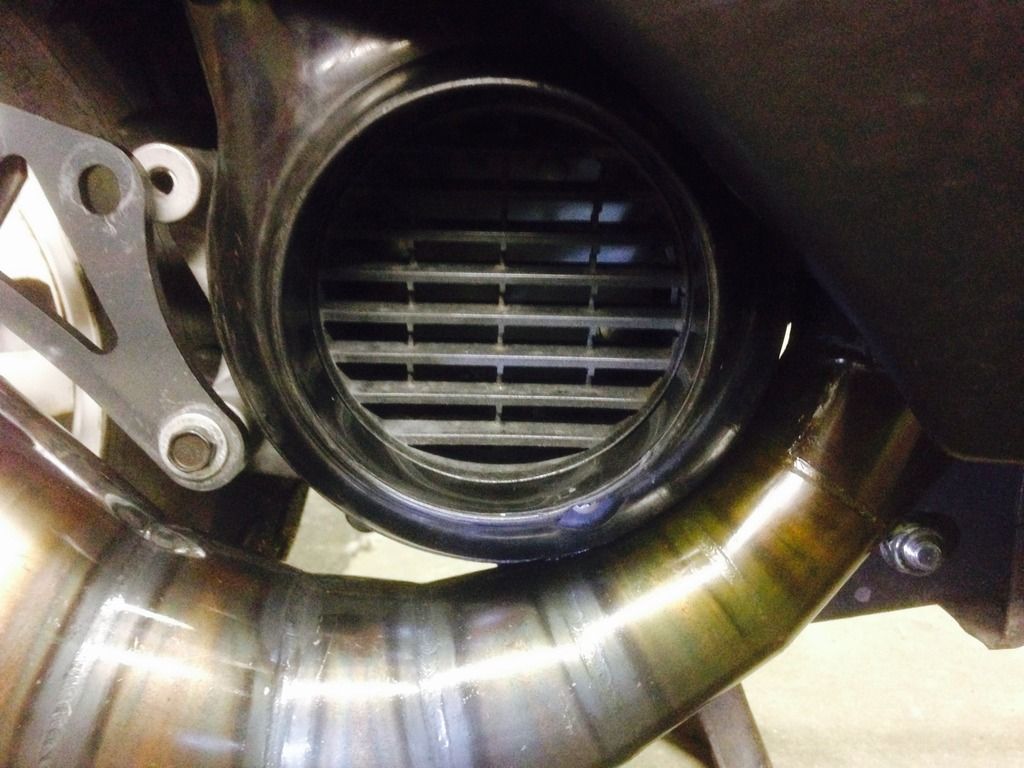

I strapped my bike down to my work bench to begin the work. Once I stripped the cases and bagged and tagged all the parts I put the cases in the blaster. My brother made this for our projects and it works great. It's so nice to do this in the heated garage instead of in the driveway.

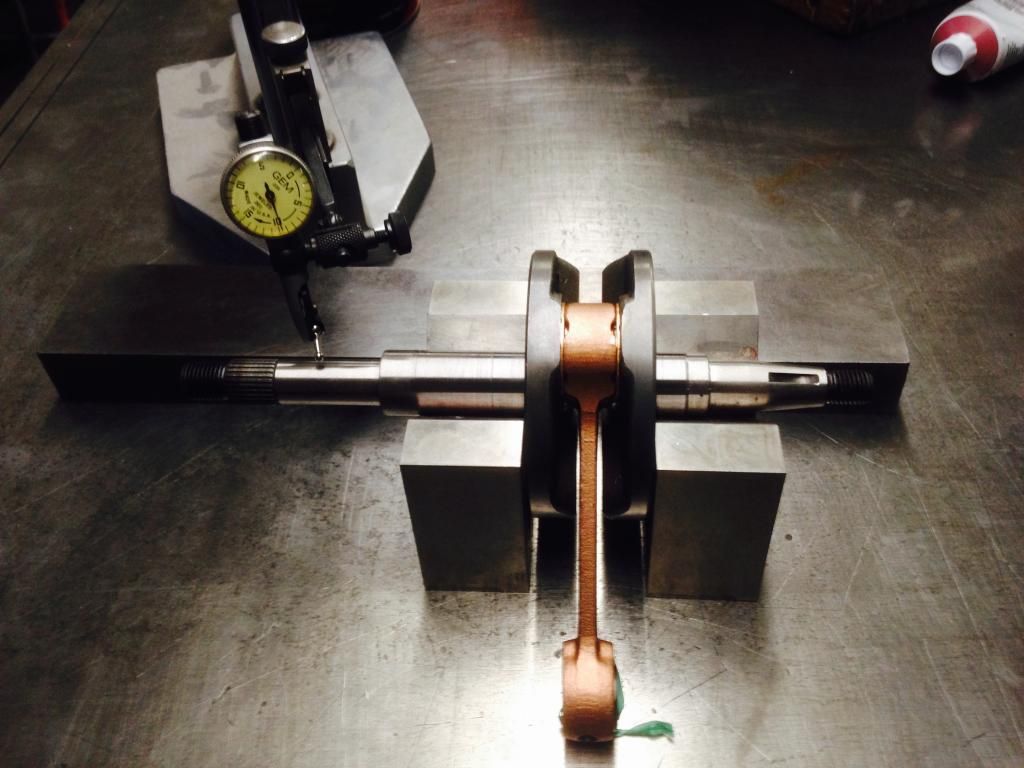

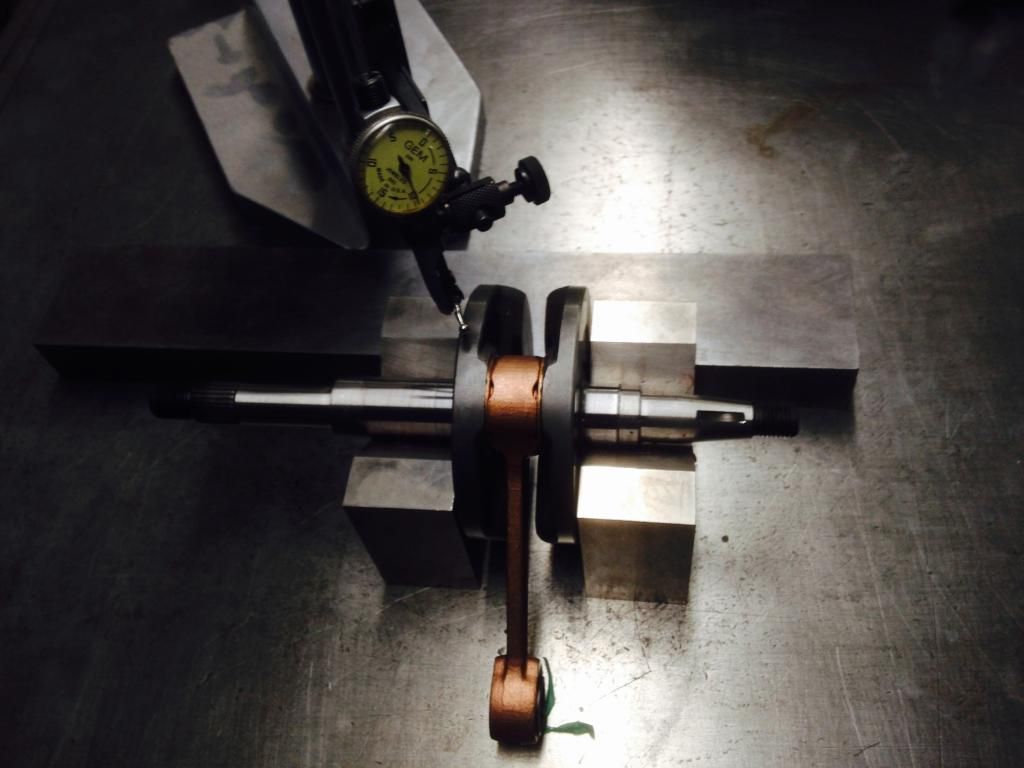

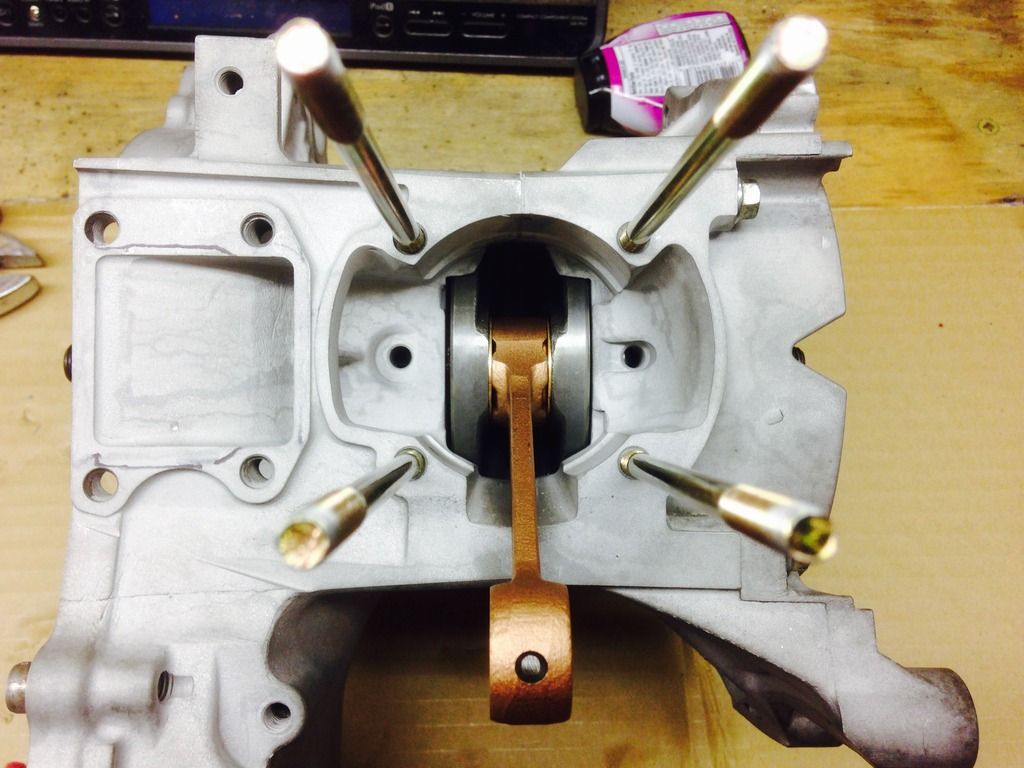

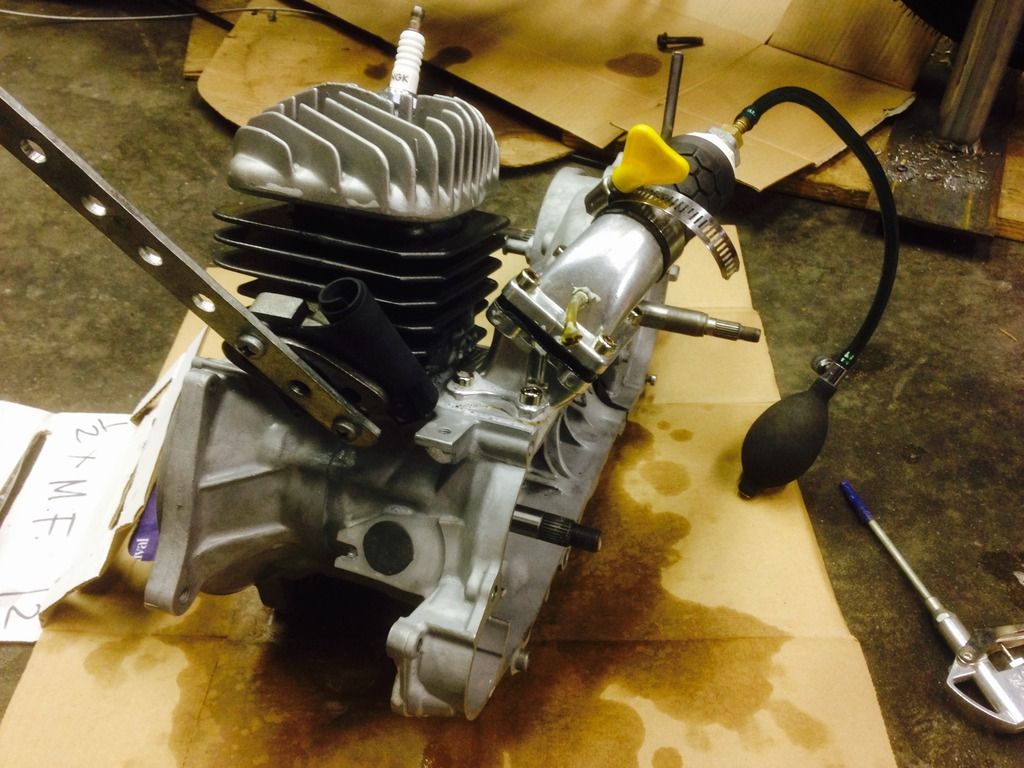

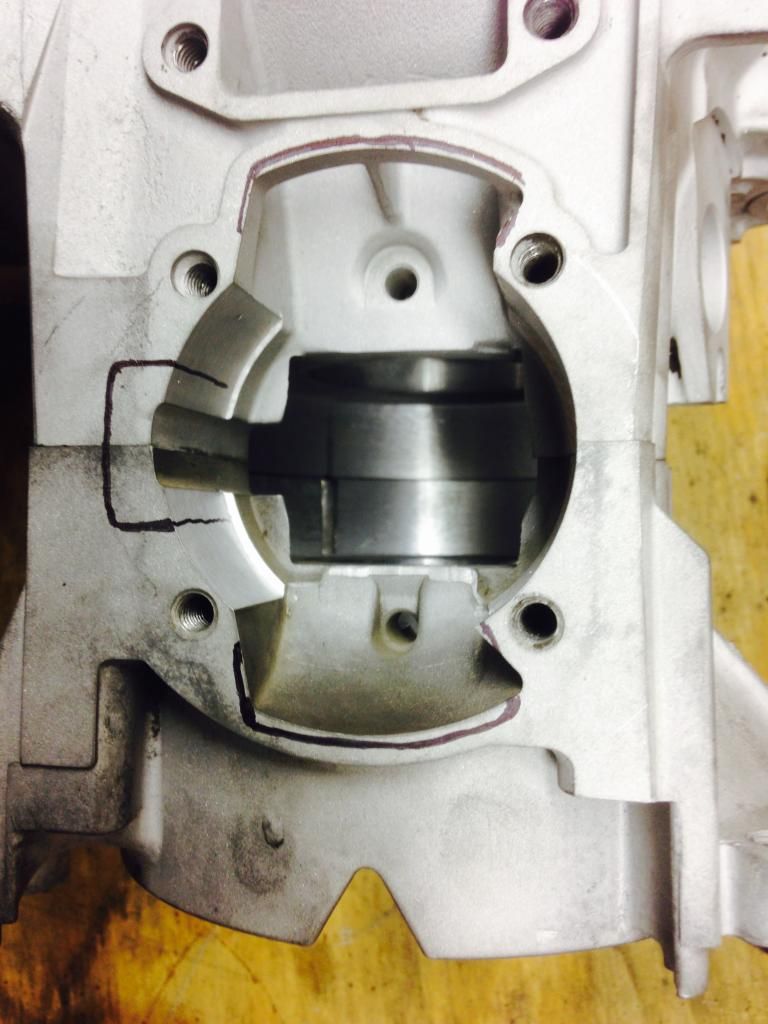

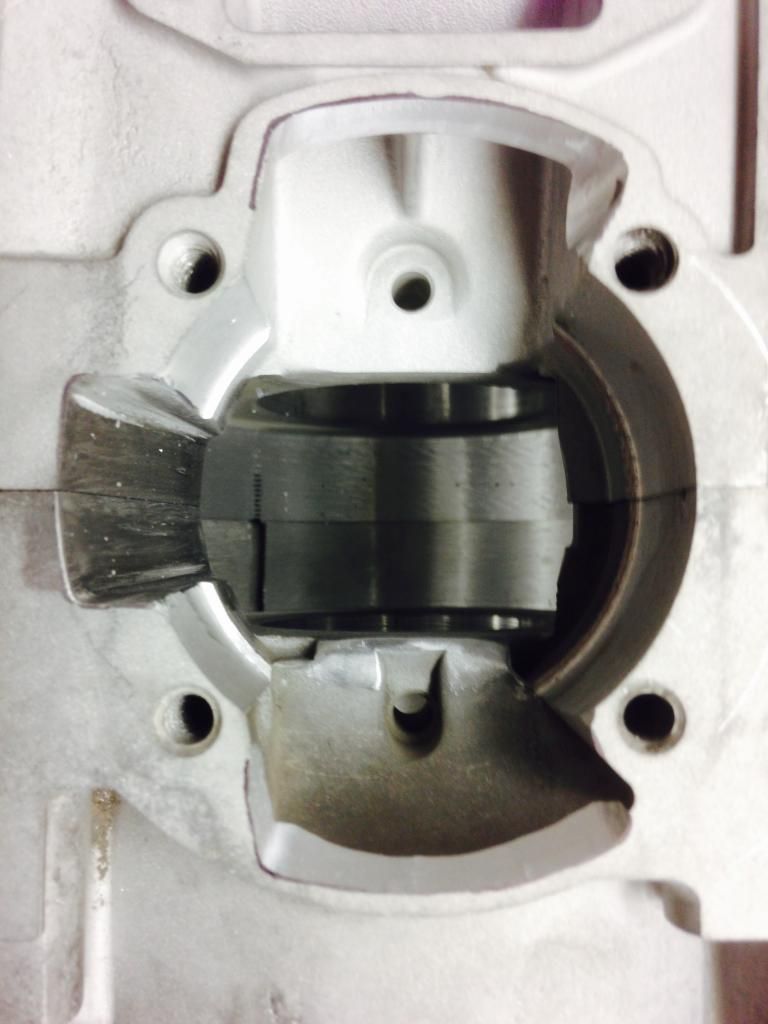

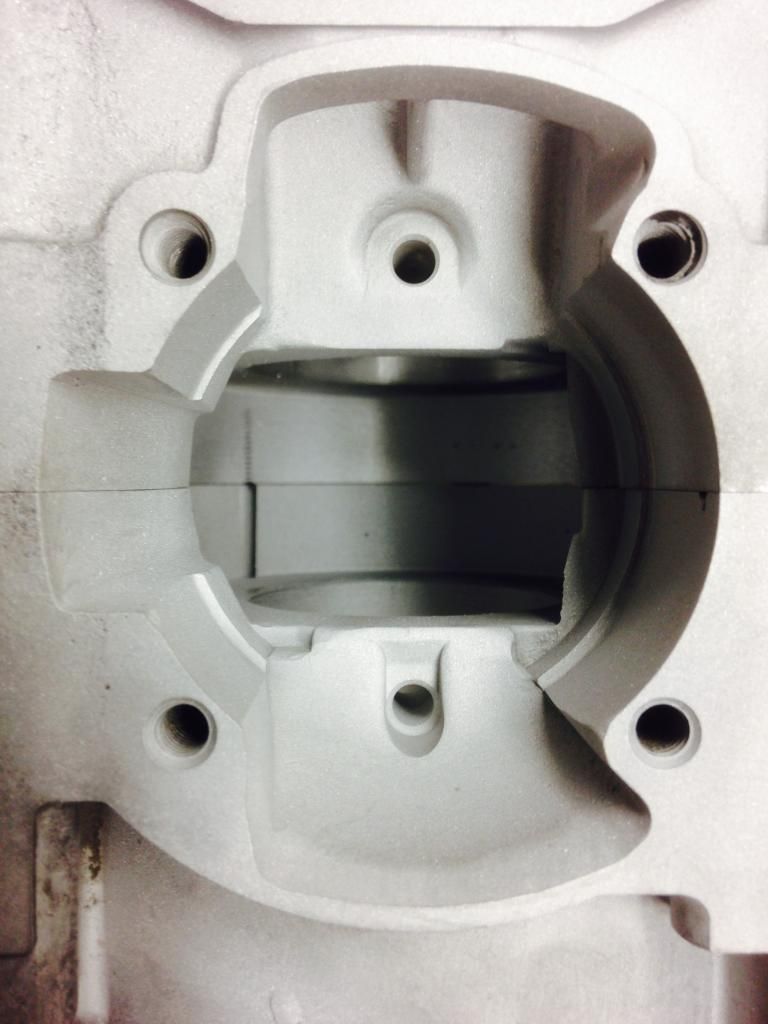

I have a friend do my machining and help with technical stuff. He is extremely skilled and knowledgeable, and is very percise with his work. Here is his current project. http://www.mopedarmy.com/forums/read.php?7,3775171 I just got my cases back from him after he machined them for the bigger cylinder skirt and larger crank.

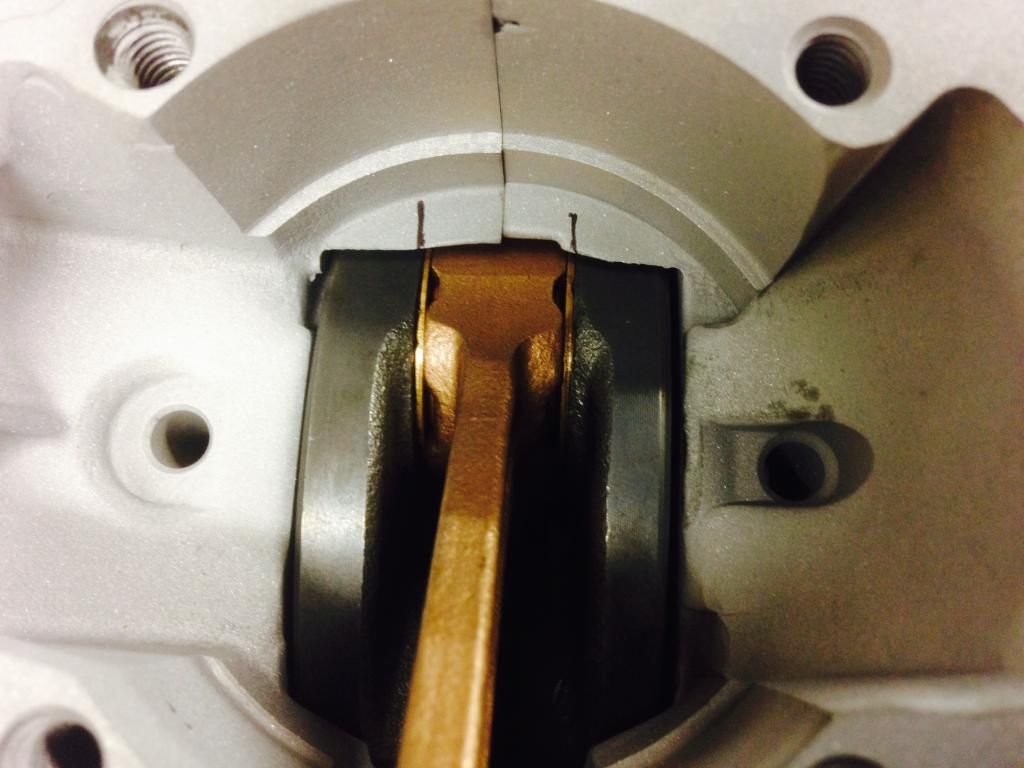

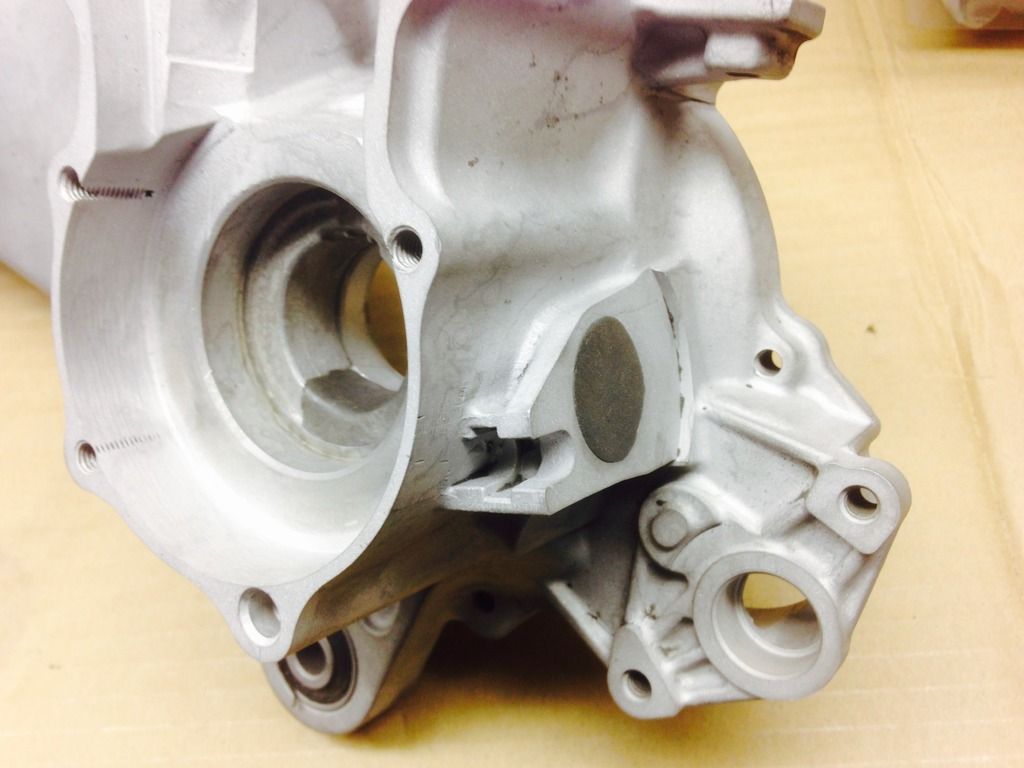

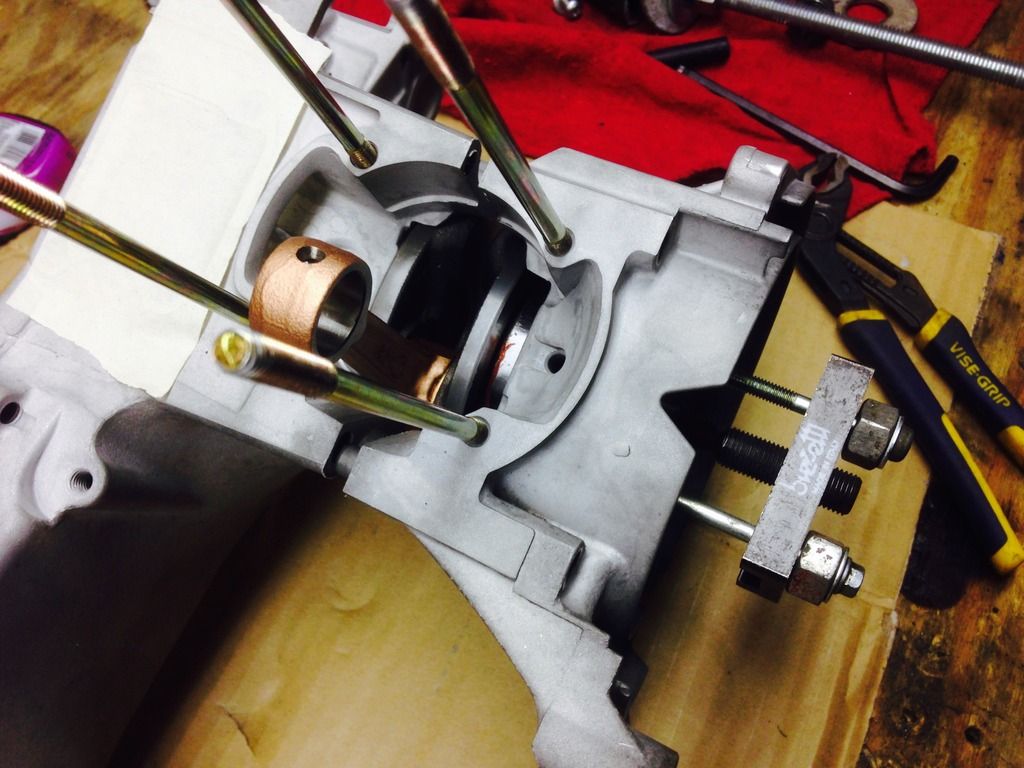

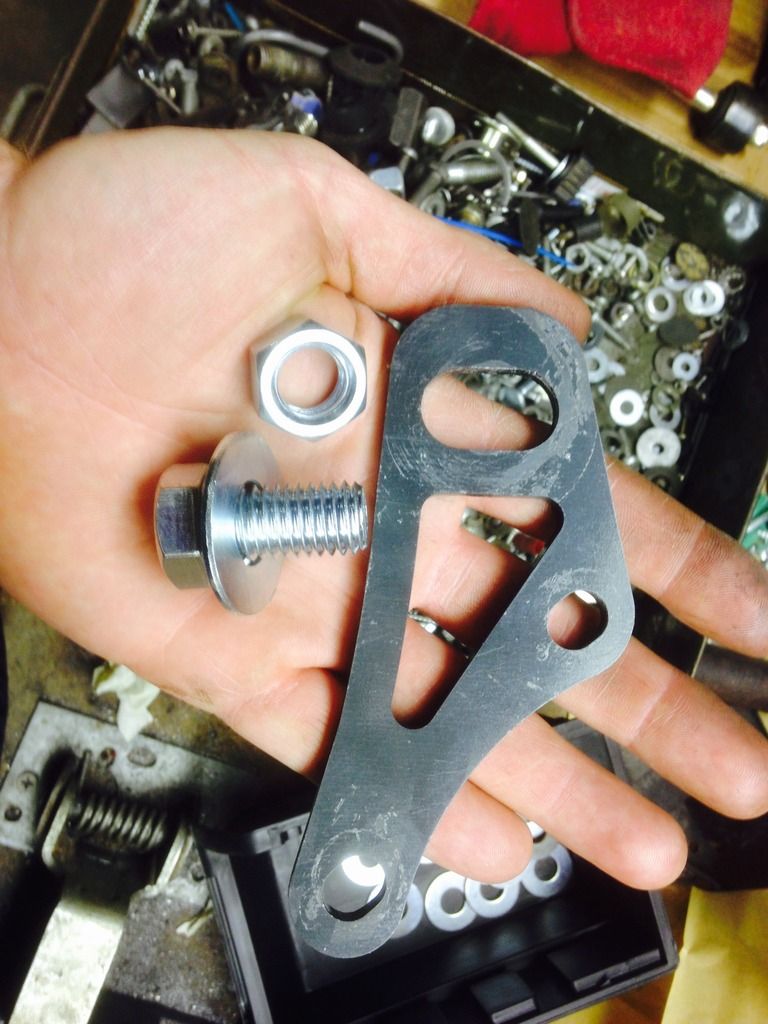

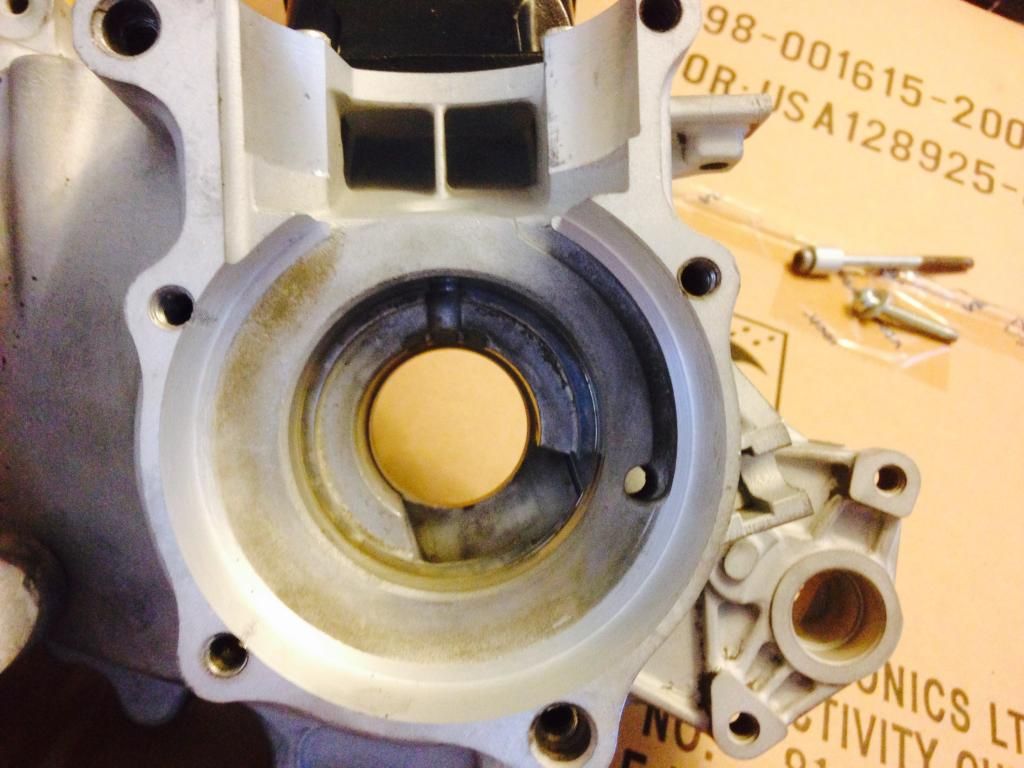

The crank is so much bigger that it causes you to machine into the holes for the case bolts. I will seal these bolt holes with copper washers and sealant. I have already ported the intake area and sand blasted the metal to give it a even finish.

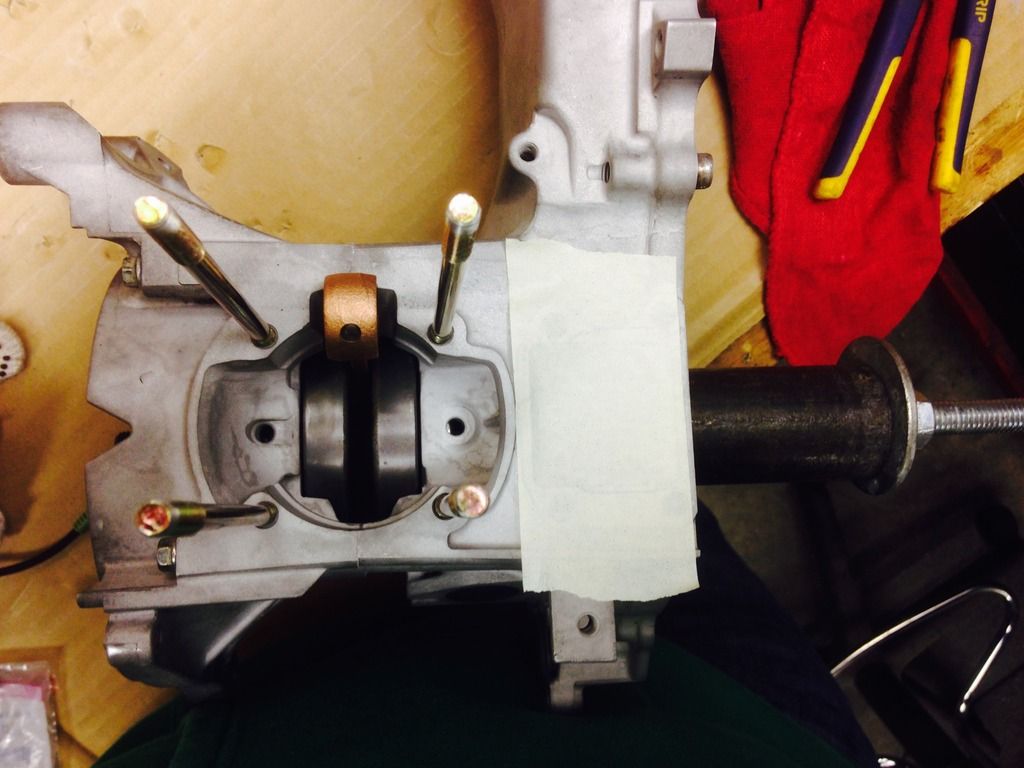

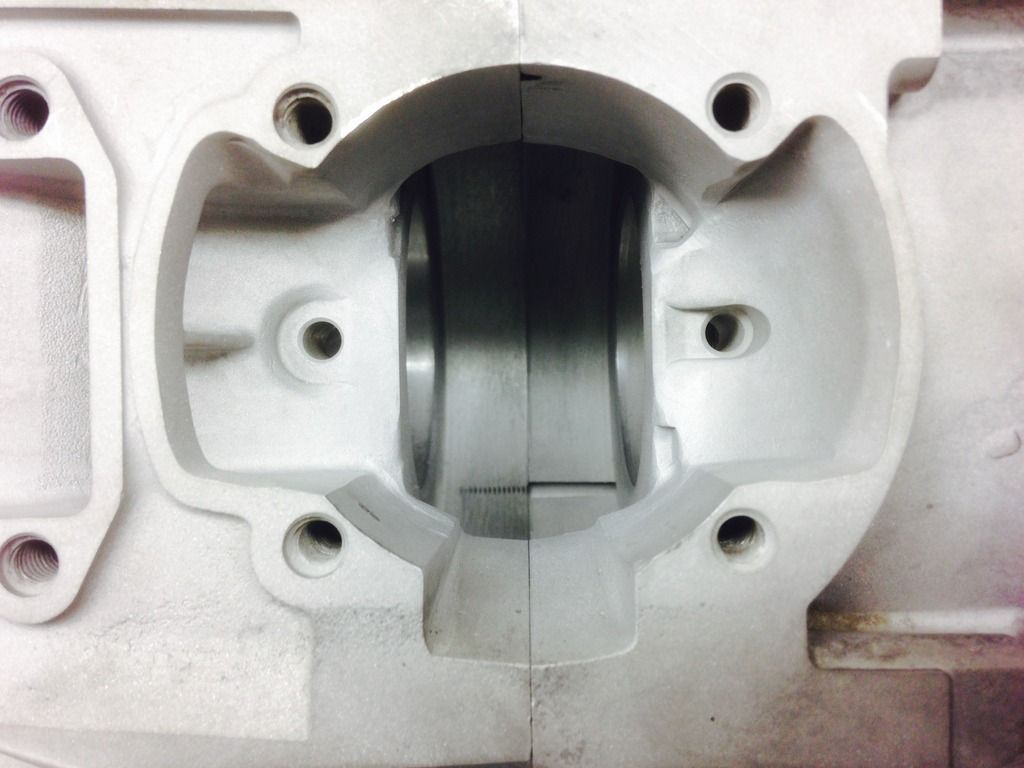

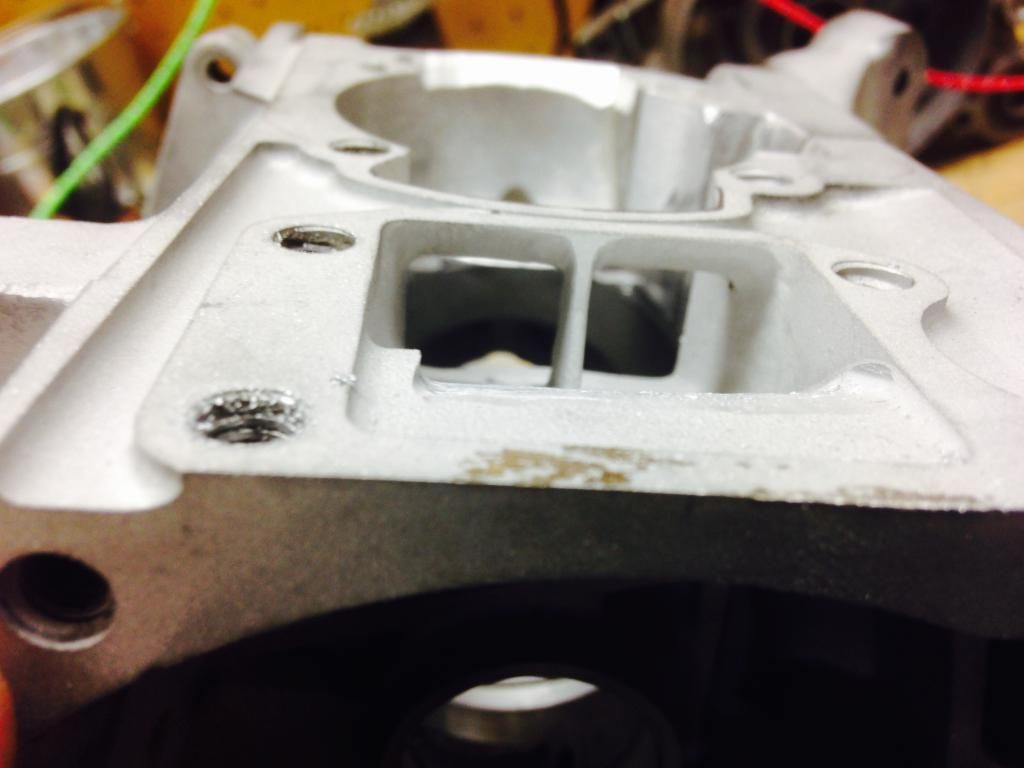

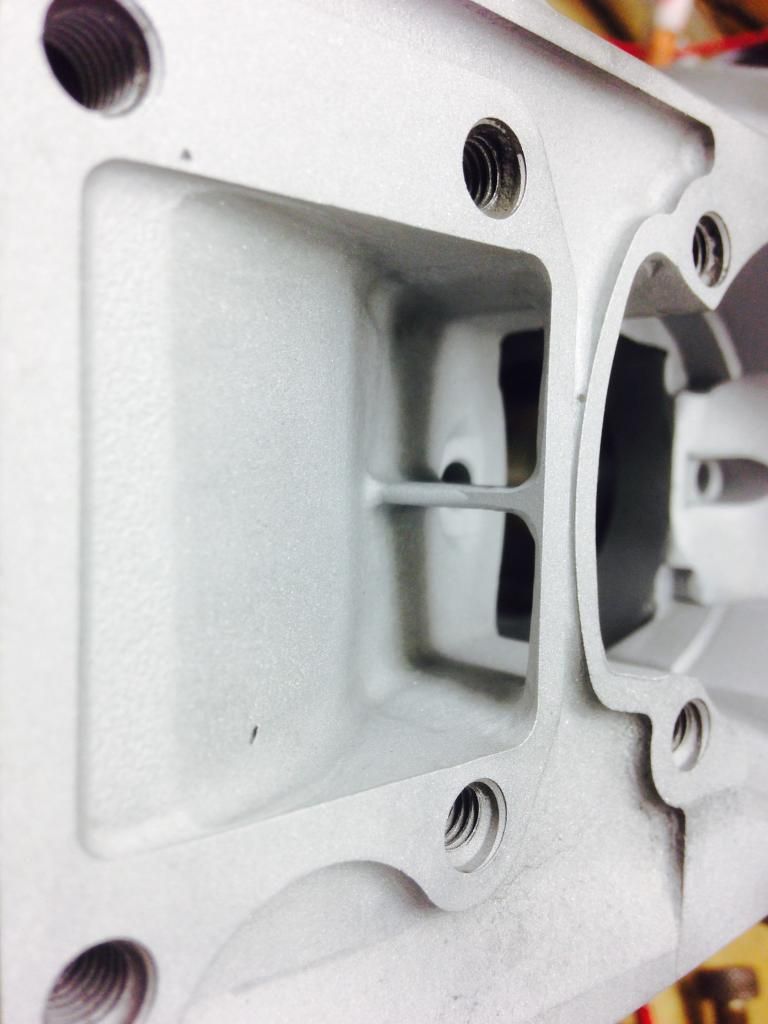

I still need to match the massive boost port. I took one of the base gaskets and laid it down on the cylinder to match it more closely. Then I will take that gasket and use it to trace the boost port on the cases. I cleaned up the transfers a little and knife edged the dividers.

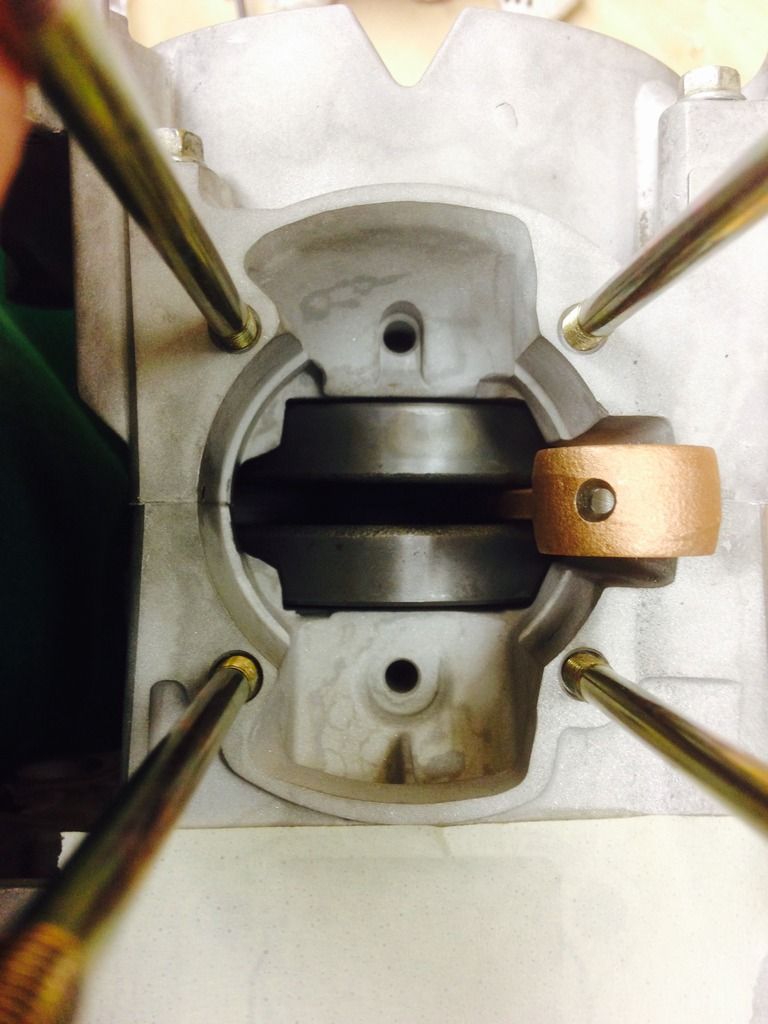

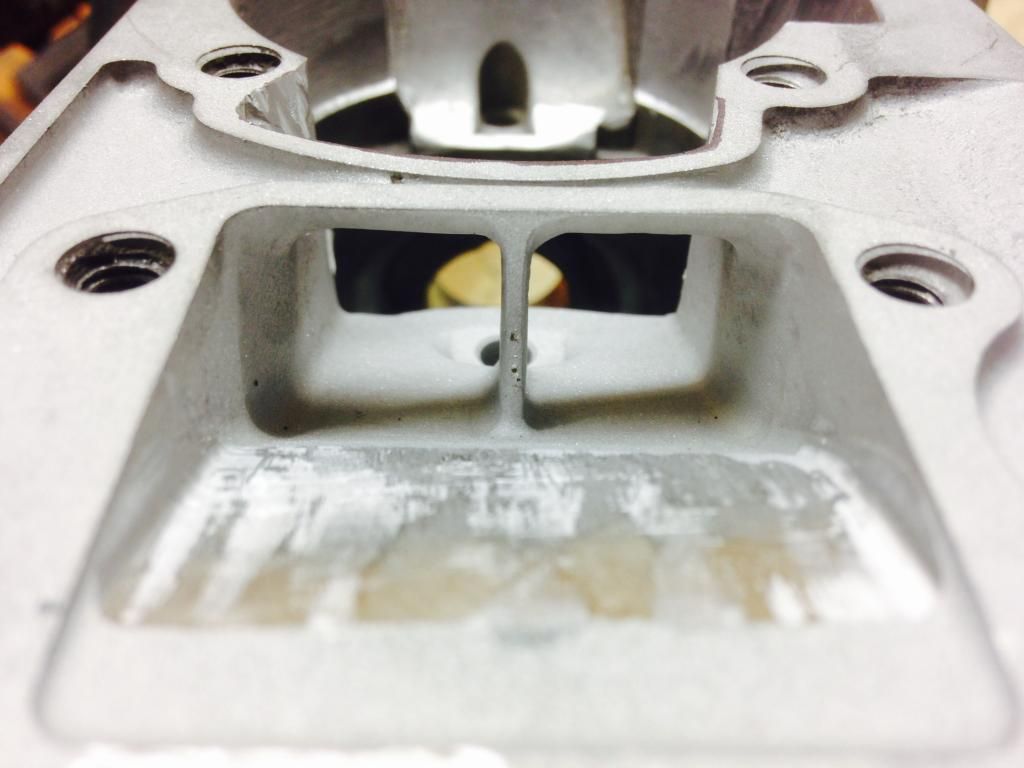

I did the case match and took the hump out of the intake. It still needs a little more work, then I will sand blast those areas to give it a nice finish.

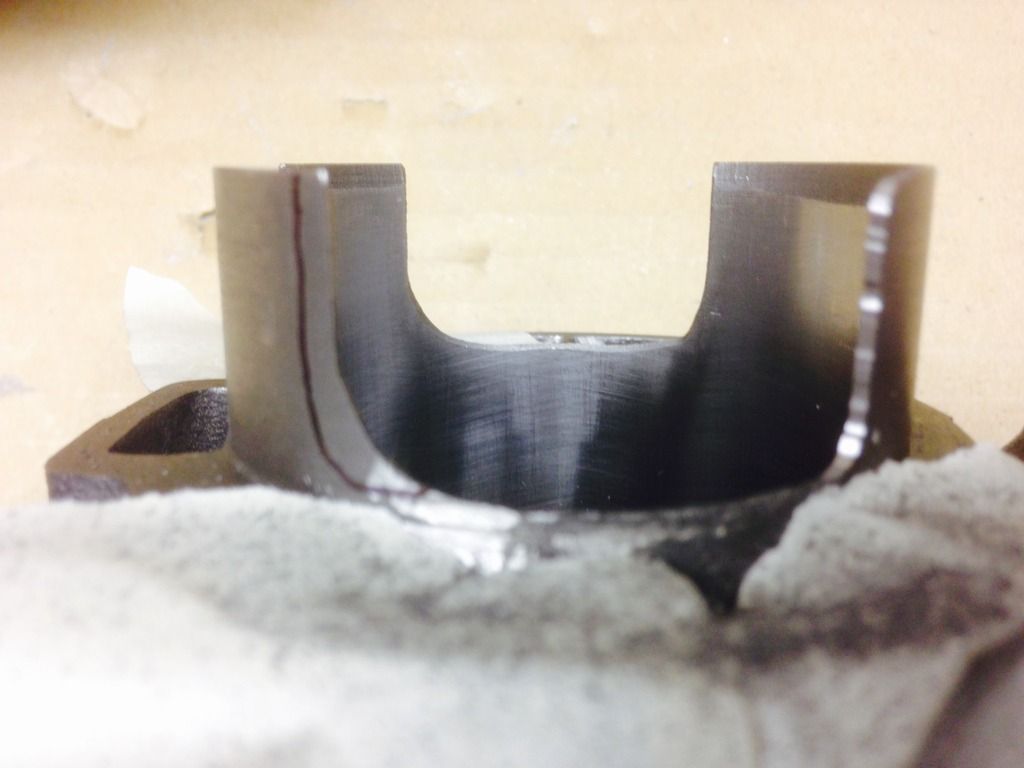

Finished all the dremel work and blasted all the surfaces. I matched the cylinder slightly where the cases were bigger then the cylinder. You can see some pits in the cases from air pockets in the castings. I might put some JBweld in there to fill it.

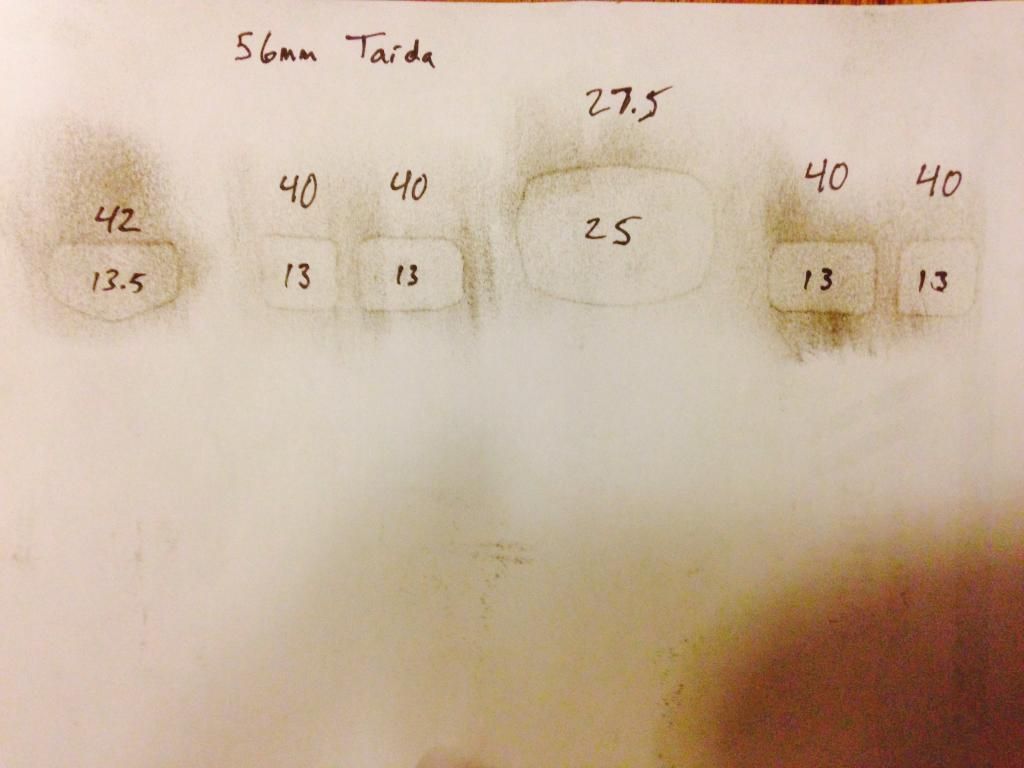

Here is the port map of the cylinder.