The design of the sight glass is pretty poor. The plastic dome and the plastic tank are made out of two different types of plastic. The dome is similar to clear (yellowish now) styrene, while the tank is either polyethylene or something similar. The plastic dome has a single male thread, while the tank has several female threads. The dome is supposed to go into the tank, and less than one turn ( about 3/4 of a turn is supposed to tighten enough to compress the rubber gasket. It doesn't. If you give it 4/5 of a turn, it will jump the single thread and become completely loose. None of the threads appear damaged. The single thread can apply a small amount of sealing pressure on the gasket, but not enough to seal. In the past, I have repaired it by using gasket sealer on the gasket and tightening the dome just to the point of popping, and that works for a month or two before the leak returns. Also, after 44 years, the rubber gasket has become pretty stiff. The gasket has "rings" so that there are two sealing surfaces.. an inner ring as primary, and an outer ring as backup. Unless I figure out a way to "grow" the single thread in the dome to make it taller, the dome will never screw in tight enough to put much pressure on any gasket.

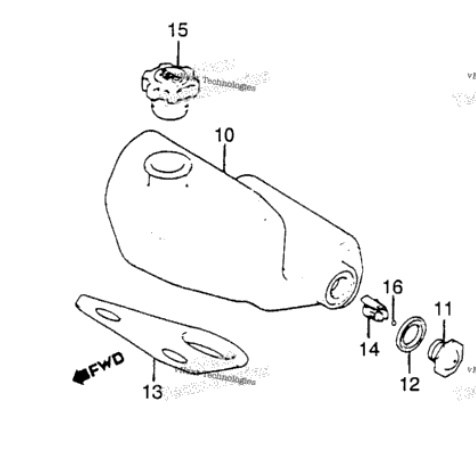

Anybody have any good ideas for a solution? Any source for new rubber "ringed" gaskets. Honda OEM gaskets have been unavailable for years, but maybe there is a non-Honda application that uses a "ringed" gasket of the same size. If the gasket were new and very soft, it might work. Here is the drawing from a Honda parts page:

http://www.vintagegarage.com/honda/OilTankDrawing.jpg